How the cargo ship becomes a hotel ship…

Which preceded:

Shall I summarize 6 months of hard work? They searched for a ship, found a wreckage, replaced the hull, did some more painting… and done! Or would you rather hear the whole story? You can read it in my previous blog and the continuation blog…

A boat is only a ship when it floats!

Have you read my previous blogs? Then now it’s time to tell the next piece. The hard work is far from over!

Where did Maurits, Olga and Boef live during the renovation?

Ah yeah, I completely forgot to tell you… oops! In the beginning they still lived in their own house in Limburg. But they sold it in September. They needed the money. Rebuilding a ship like that is quite expensive… It was the intention to just bivouac in the deckhouse (= skipper’s house). And then they were lucky: Maurits brother temporarily had a house left. So they made eager use of it! Not just to sleep. Also the new inventory and their own stuff from their old house could be stored there. So they had a roof over their heads and heating too!

The hatch cover turns into a sun deck…

Did you get a good look at a Luxemotor ship? From front to back it’s as crooked as a banana. It’s what they call a beautiful “sheer”. So the head (= front) and the butt (= rear … ah you knew?) are higher than the middle. This makes it sail better through the waves. I’m not sure if that’s also true for a banana?

In any case Olga and Maurits had fallen for the beautiful lines of the ship. This had to stay that way. The old cover consisted of wooden planks that were laid on battens. According to the old owner these planks were a bit rotten, but “he knew where the good pieces were”… he walked swiftly over the planks. Olga & Maurits often thought of those words. When they carefully took away the old planks one by one, they just broke into pieces. That skipper had been very lucky!

When the planks and slats are gone, you’ll see the hatchside coaming (the whole of the hatchside coaming and the markers is the pine…those nautical terms!) and I’m not even allowed to lift my paw against it… See all those notches? Of course no new deck will fit on top. The edge was burned off just about equally everywhere and exactly the same piece was welded new. Right! This way the same “sheer” was maintained!

New sundeck…

In the new hatchside coaming holes were burned for the windows. On top came a new sundeck, like a lid on a box. Do you see that the 2nd exit is there now? And also a lot of things have changed at the front. Dief is looking for the bench to lie on, but it isn’t there yet. The storage lockers are, although the lids are still missing.

It’s December now. Luckily there is little frost or snow and they can work their way through. It are long days. How happy they are with a comfortable warm house to shower and sleep!

Start of the interior design…

The outside looks already good. Inside… there’s still work to be done!

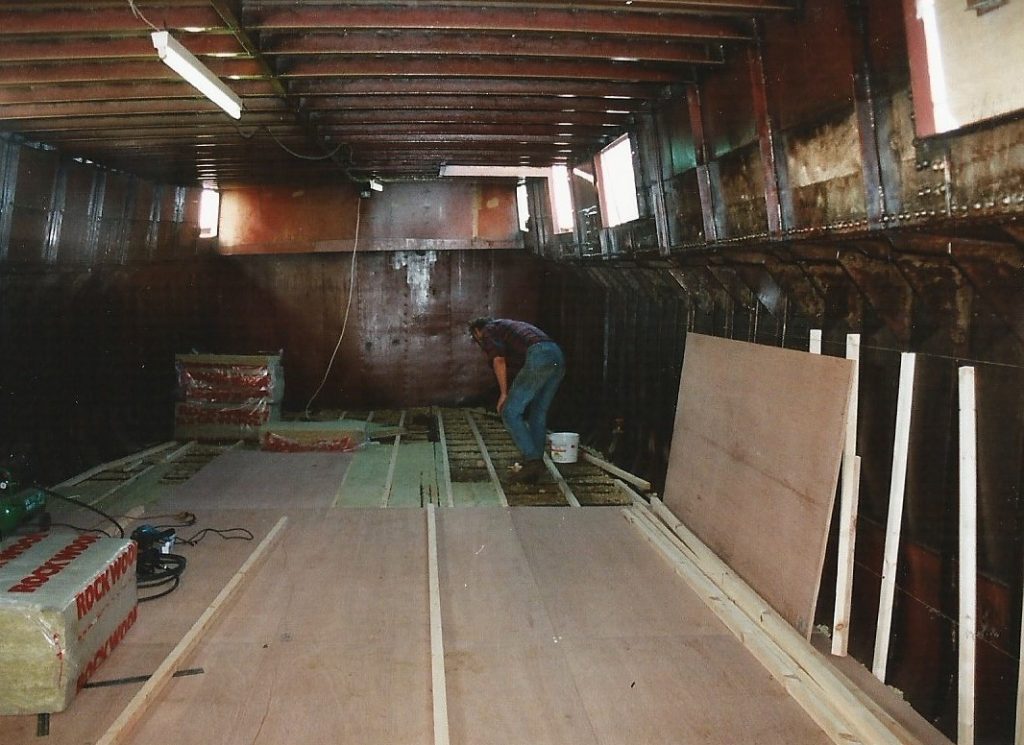

The hold is empty. The rust, dirt and cement are gone. There was also some kind of sticky oil on the hull and that had to be removed as well. It was quite a job to scratch that away between the rivets. But it was done and a new layer of oil was applied.

A cargo ship has been constructed to carry cargo. Without cargo it floats very high on the water, almost above it. You can’t sail well that way and all the passengers together don’t carry much weight…

So there had to be ballast in it! They chose loose pebbles to fill the space between the frames. According to the calculation this had to be heavy enough. The truck dropped it to the shore. With wheelbarrows it had to go through the window. They inserted a plastic funnel through the window with a trunk. That way it could be divided a bit. The finishing had to be done with a rake… I told you it was hard work!

The floor goes in… and out again!

The load of pebbles is between the frames. On the frames are wooden battens… …screwed! On top of the cross bars came wooden beams. Start counting how many holes it takes… …and how many drill bits broke on that hard steel.

Between the beams the space was nicely filled with insulation, rockwool. It literally gave Olga the creeps and she left it to Maurits as much as possible. And then the floor could be put on, sheet by sheet. Nice measuring and sawing to fit everything. Yeah, my bosses learned a lot then!

And then you might think, “So, that floor’s finished? But all those sheets had to come out… . Maurits drew on the sheets where all the walls had to be put. That way Maurits also knew where all the pipes for electricity and water had to pass through the floor. Sort of a huge puzzle, don’t you think?

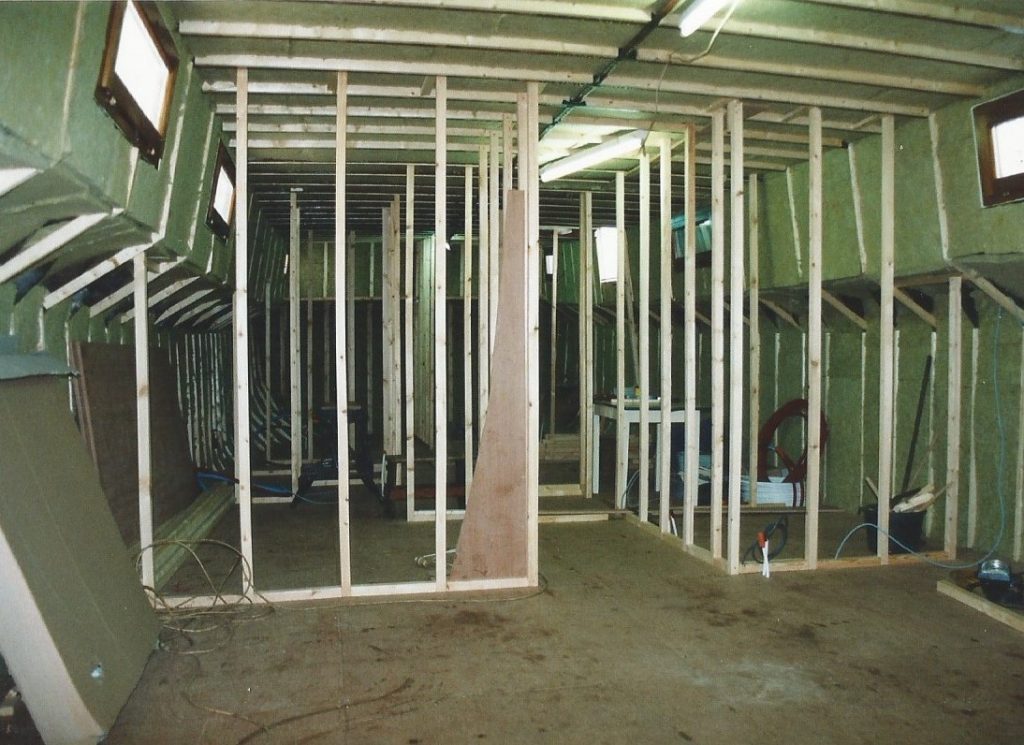

Maurits got his floor. Olga didn’t have to be bored. A lot of battens were needed on the upright frames, on the side and on the ceiling. And whole packs of insulation too, of course. That is why it is now comfortable on board!

The walls of the cabins get their place:

So the floor’s in. The pipes peep out in the right places. If you want to know how many meters, or even kilometres, were needed, just ask skipper Maurits!

Do you see the carpenter delivered the windows? It’s now January. With the windows closed, the insulation and a radiant heater, it is much more pleasant to work!

And now the walls. Do you recognize the cabins, with the hallway in between?

Still, it wasn’t as easy as it seems. Very different from being ashore or in a house… How do you make everything square? A water level or a plumb line is no good! The more weight you put in front of the boat, the more the ship tilts forward. Or the other way around…

How do you think they solved that? You got a week to figure that out, because my writing paw hurts.

…is being continued…

PS Maybe you want to see what the ship looks like as a cruise ship now as well? In this blog I’ll take you on a tour through my house!